Epoxy Coated Dowel Bar

EPOXY COATED DOWEL BAR

The Epoxy Coated Dowel Bar is a strategic connection element designed to transfer vertical and horizontal loads between concrete blocks, preventing relative motion and deformations.

The use of this innovative solution allows the weight of moving tools to be distributed among multiple concrete blocks, eliminating potential deformations and ensuring stability.

How the application projects of dowel bars are implemented?

Epoxy Coated Dowel Bar projects are implemented in 3 different methods

3- Projects can be implemented in not only newly-constructed but also previously constructed areas. These areas are drilled/cut and Epoxy Coated Dowel Bars are placed in those areas for the purpose of concrete reinforcing.

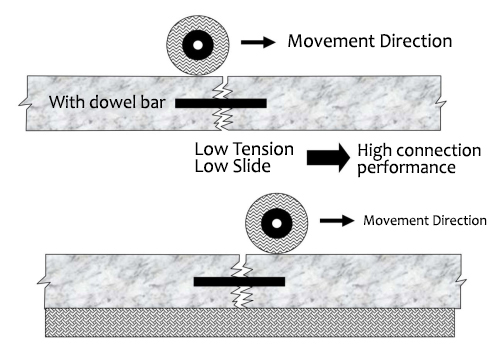

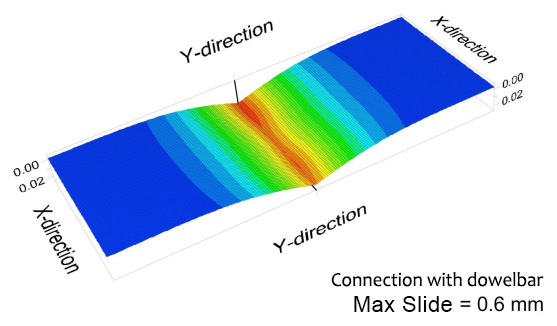

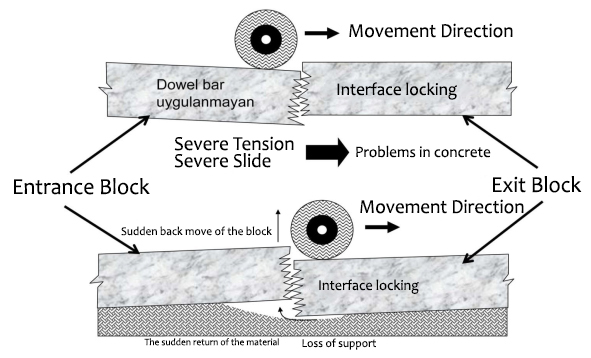

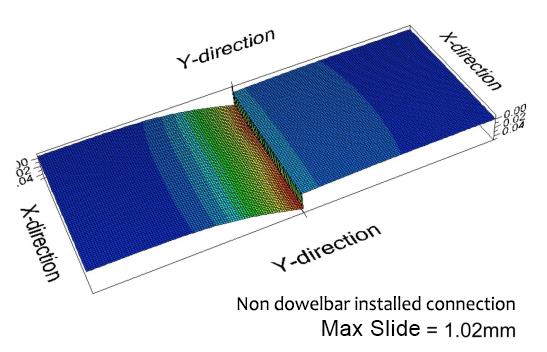

However, such damages will not occur when Epoxy Coated Dowel Bars are applied under the concrete road. High connection performance of the dowel bars ensure reinforcement between concrete blocks. Thereby, the load on concrete road will be evenly distributed to the entire concrete regardless of the amount of load on the concrete road and any probable slumps or damages will be avoided.

Epoxy Coated Dowel Bar is commonly used in the construction of aerodromes, aircraft parking areas and concrete roads and fields with high strength.

Epoxy Coated Dowel Bar is manufactured in different calibers and lengths upon the requests of the customers in line with the principles of technical specifications and in accordance with standards.

In developed countries, construction sector plays a significant role in national economy and determination of the standards of living in those countries.

As the construction sector develops, the number of buildings such as airports and concrete roads increases as well. However, what matters is quality and durability of such constructions rather than their quantities. Therefore, it is very crucial to use Epoxy Coated Dowel Bar in construction to prevent deformations.

Epoxy Coated Dowel Bar is commonly used in the construction of airports and concrete roads which require high endurance. Epoxy Coated Dowel Bar moves between joints in strategic points and ensure stretching of the concrete blocks, distribute the load on concrete blocks to entire ground equally and prevent the concentration of the pressure on a single point. Since the pressure is equally distributed over the ground surface, different deformations such as slump, cracks and disintegration etc. are avoided.

Prior to the application of the concrete floors, the points of Epoxy Coated Dowel Bar application are determined. These points are also joint cutting points. Epoxy Coated Dowel Bars are placed in these points and the concrete is poured and application is completed.

When it is correctly designed and applied, dowel Bars, tie bars and rods significantly increase the efficiency and extend the life of road pavements.

In USA and Europe, the use of Epoxy Coated Dowel Bars which are manufactured in ASTM Standards in airports and highways are stipulated in technical specifications as standard.

Epoxy Coated Dowel Bar products and equipment are manufactured from bars rolled from carbon steel billets especially in compliance with ASTM A615/A 615M, ASTM A675/A 675M, ASTM A706/A 706M ve ASTM A1035/A 1035M standard quality.

The surfaces and ends of Epoxy Coated Dowel Bars are cut straight and coated with epoxy paint in compliance with ASTM A775/A775M standard. The reason for coating of Dowel Bars with epoxy paint is to prevent any probable corrosions which may occur after a while.

Epoxy Coated Dowel Bars are manufactured in line with ASTM A615/A615M, ASTM A675/A675M, ASTM A706/ A706M ASTM A1035 standards or in line with tensile and breaking values requested.

Epoxy Coated Dowel Bar products are manufactured according to the measurements determined by the customers. Epoxy Coated Dowel Bars with specific measurements are manufactured in accordance with technical specifications and standards.

The manufacturing phase of the Epoxy Coated Dowel Bars are inspected and audited with quality control systems and the relevant reports are delivered to the customer along with the products. Epoxy Coated Dowel Bar can be used during the construction process and for the purpose of reinforcement of the previously constructed areas as well.

The diameters of the Epoxy Coated Dowel Bar varies according to the requests of the customer. However, they can be manufactured as 12, 16, 20, 25, 30, 40, 50, 60, 70 and 75 mm as standard from 400 to 800mm length.

Following the completion of the production of Epoxy Coated Dowel Bar, another significant issue is the package of the products considering the time and cost calculations. Manufactured Epoxy Coated Dowel Bar products are generally shipped in wooden crates prepared on europallets in line with international maritime, road and container transportation as packaged and covered with pvc covers.

Each Epoxy Coated Dowel Bar is placed in PE matt tubes in compliance with ASTM A775/A775M standards. Thereby, the Epoxy Coated Dowel Bar is shipped without any damage in accordance with European standards. Furthermore, we can pack the products in any preferred package form according to the requirements of the projects.

Technical Specifications

Epoxy Coated Dowel Bar is steel equipment coated with epoxy paint and designed for the use in infrastructure of concrete roads which require high endurance.

Why dowel bars are coated with epoxy paint?

Dowel bars are coated with epoxy paint in order to prevent any probable corrosion. Because, the concrete has high level of PH inside. Power of Hydrogen called as pH is a unit of measure which defines the degree of acidity and alkalinity of a solution. A passive oxide layer occurs on the concrete surface because of the pH inside the concrete. This passive oxide layer protects the concrete and prevents any corrosion. However, chlorine ions occur during naturally occurring rains, sea water or thawing of ices. When these chlorine ions contact with the cement inside the concrete, pH level inside the concrete decreases and protective passive oxide layer loses its function and cracks and breakings occur on the surface of the concrete. These cracks and breakings also cause the formation of corrosion. And these corrosions reach steel equipment and cause corrosion and volume expansion on dowel bars. Such expansion and corrosion increase the internal damage and cracks caused by the dowel bars inside the concrete. For that reason, it causes deformations and material damages on outer surface. However, epoxy paint creates a physical and electrochemical barrier against corrosions and ensures a superior protection. Epoxy paint isolates the iron and prevents the corrosion at the rate of 98%.

What is the life cycle cost of the coating of dowel bars with epoxy paint?

Recent studies in Turkey show that corrosion causes a significant material damage. It is stated that the annual material loss caused by corrosion is between 23 to 45 billion USD in average in Turkey.

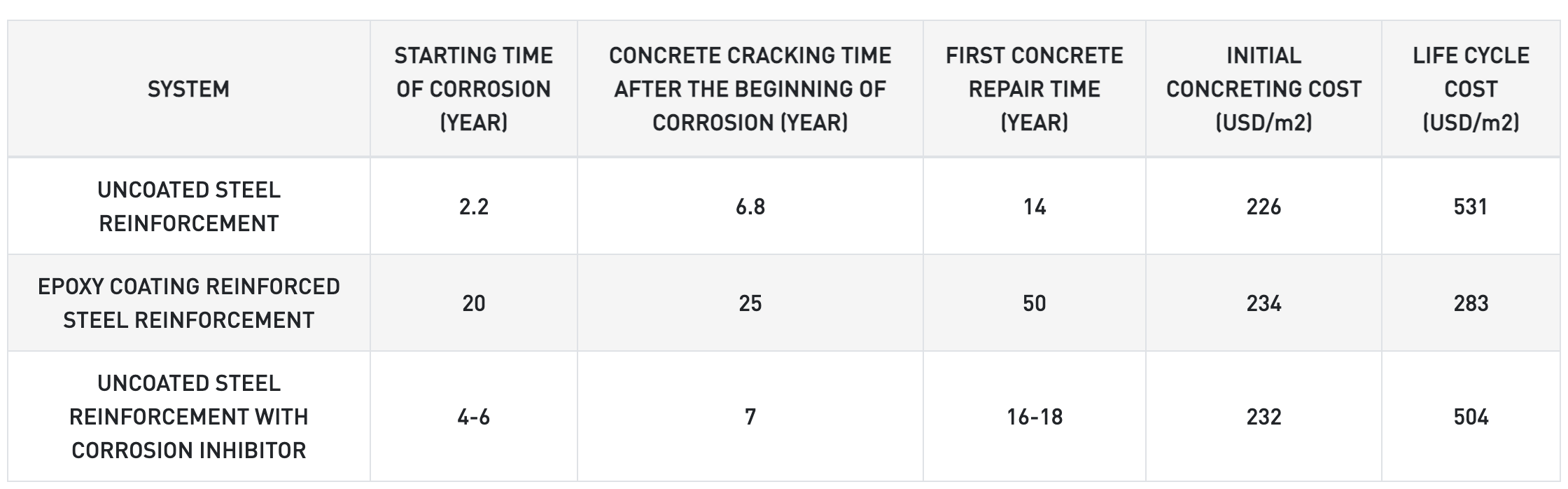

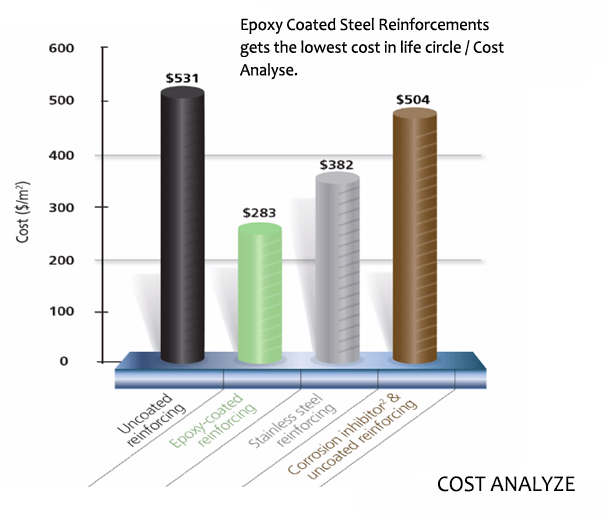

The study of Kansas State University on repair and cost life cycle of the steel equipment coated with epoxy paint clearly indicates the benefits and advantages of this application.

That is a serious delusion not to prefer Epoxy Coated Reinforcements in construction phase in order to slightly decrease the project costs. The material and nonmaterial losses and damages as a result of corrosion occurring within years cause more and more material losses. The table below indicates the graphs for material losses in years. It can be seen that the rates which increase the initial cost by 3,7% per square meter would provide many times more advantages in 50-year life cycle statistics

What is the strenght of the bond between epoxy coated dowel bars and concrete?

It is completely incorrect that epoxy-paint coating decreases the adhesion of a steel equipment to concrete. Epoxy-paint coating of the surfaces extends the life of steel equipment and ensures better cohesion to concrete and full protection on entire area. The tests performed indicated that the cohesion force of epoxy-coated dowel bars to concrete is significantly higher than other products not coated with epoxy.

What is the intended use of the dowel bars?

The use of dowel bars is very important especially in construction of concrete roads and airports which are exposed to heavy load and pressure. Because, the grounds in these locations are exposed to tons of loads. In case of absence of a support force inside such concrete blocks, some deformations, slumps and breakings occur in time. These slumps may cause both material losses as well as losses of souls.